Our website uses cookies to improve our website and improve the user experience.

If you continue to browse this site without changing your browser's cookie, you are deemed to agree with our cookie use policy.

News

2025/10/02

Rethinking AD Validation: Addressing the Challenges of a System-Level Approach

The concept of system-level validation in ADAS and autonomous driving development is gaining momentum, but it’s not without controversy. In this post, we summarize the most frequently discussed issues and outline how current technologies and methodologies are evolving to meet them.

Read more-

LiangDao Completes TISAX Assessments in Germany and China – Strengthening Global Trust in Automotive Information Security2025/08/07

LiangDao Completes TISAX Assessments in Germany and China – Strengthening Global Trust in Automotive Information Security2025/08/07 -

Tech.AD Europe 2025 – Insights and Innovations in AD Validation2025/03/24

Tech.AD Europe 2025 – Insights and Innovations in AD Validation2025/03/24 -

LiangDao wins 2025 Tech.AD Award for intelligent data manufacturing toolchain2025/03/21

LiangDao wins 2025 Tech.AD Award for intelligent data manufacturing toolchain2025/03/21 -

Highlights from the Autonomous Driving Meetup hosted by LiangDao2024/11/13

Highlights from the Autonomous Driving Meetup hosted by LiangDao2024/11/13 -

LiangDao relocates Berlin hub to lead innovation and automotive excellence2024/09/30

LiangDao relocates Berlin hub to lead innovation and automotive excellence2024/09/30 -

Tackling the Long Tail Problem in Autonomous Driving: Insights from Auto.AI Europe 20242024/09/26

Tackling the Long Tail Problem in Autonomous Driving: Insights from Auto.AI Europe 20242024/09/26 -

LiangDao Intelligence Wins Data Service Project for L3 Mass Production Vehicle Models2024/02/19

LiangDao Intelligence Wins Data Service Project for L3 Mass Production Vehicle Models2024/02/19 -

LiangDao Intelligence Data Solution Awarded Honorable Certification at the 2023 Intelligent Vehicle Golden Globe Awards2023/12/15

LiangDao Intelligence Data Solution Awarded Honorable Certification at the 2023 Intelligent Vehicle Golden Globe Awards2023/12/15 -

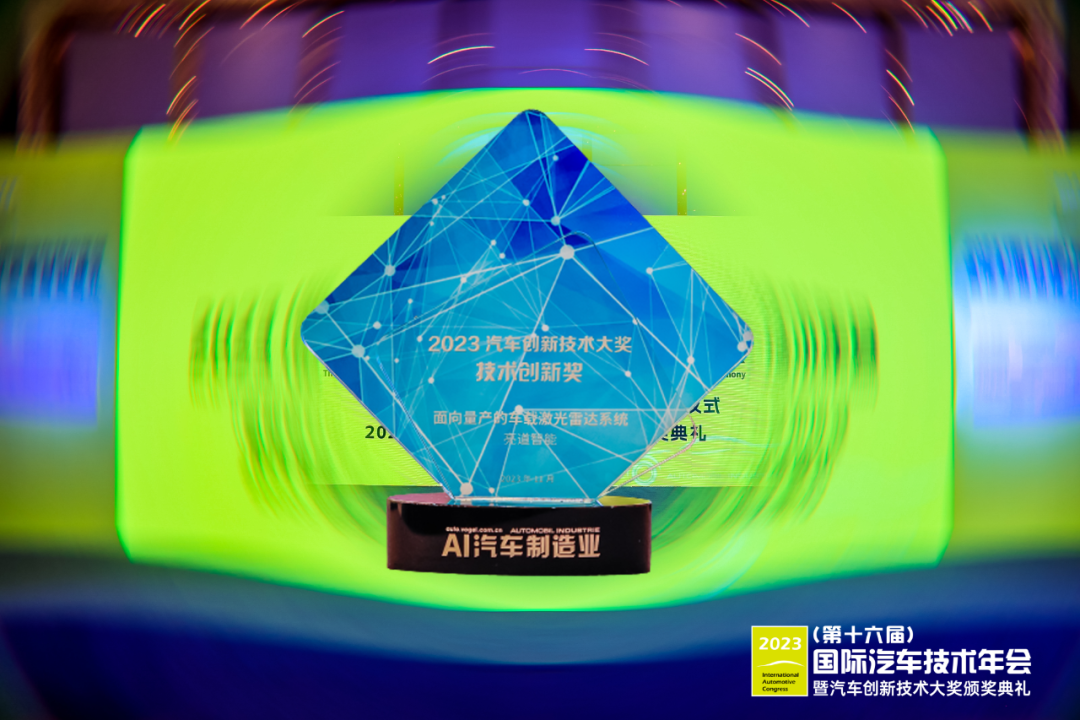

LiangDao Wins Technology Innovation Award at the 2023 Automotive Innovation Technology Awards2023/11/10

LiangDao Wins Technology Innovation Award at the 2023 Automotive Innovation Technology Awards2023/11/10 -

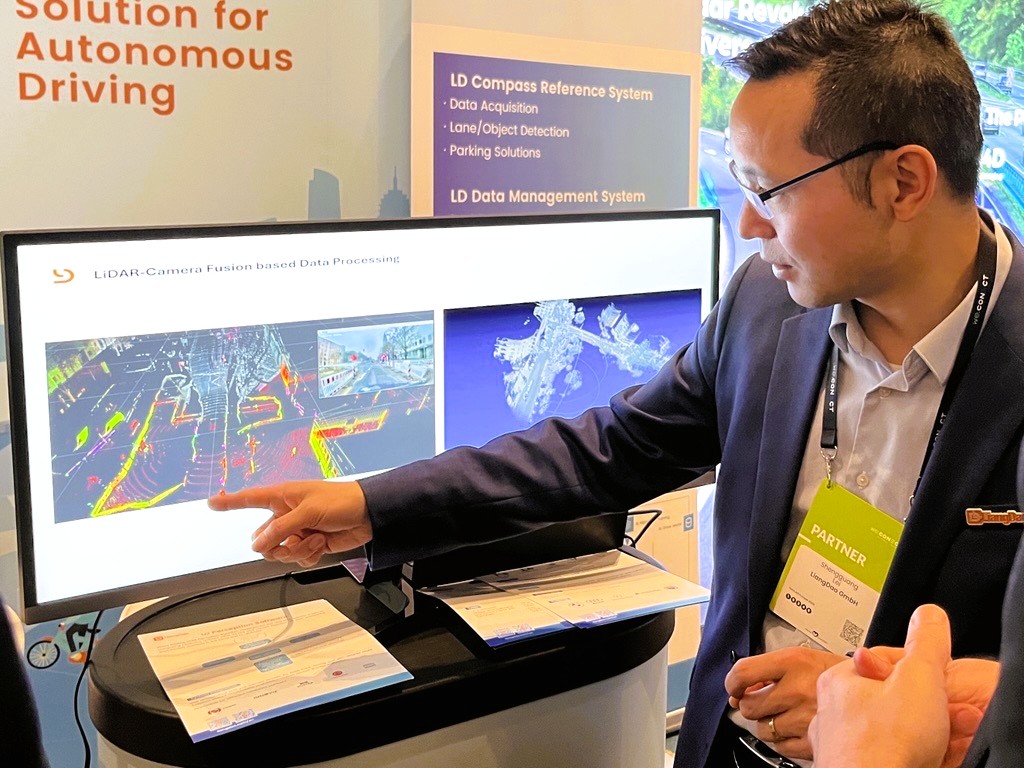

LiangDao:Complementing each others advantages, China and Germanys automotive industry work together2023/11/09

LiangDao:Complementing each others advantages, China and Germanys automotive industry work together2023/11/09 -

Journey to the Future of Mobility! LiangDao Intelligence meets you at the 29th ITS World Congress in Suzhou2023/09/28

Journey to the Future of Mobility! LiangDao Intelligence meets you at the 29th ITS World Congress in Suzhou2023/09/28 -

LiangDao Intelligence Once Again Ranked in the "KPMG Chinas Leading Autotech 50" List2023/09/14

LiangDao Intelligence Once Again Ranked in the "KPMG Chinas Leading Autotech 50" List2023/09/14 -

LiangDao becomes ecological partner of the Traffic Safety Behavior Science Laboratory2023/07/28

LiangDao becomes ecological partner of the Traffic Safety Behavior Science Laboratory2023/07/28 -

LiangDao Intelligence Successfully Wins Series Production Order from the American OEM2023/05/05

LiangDao Intelligence Successfully Wins Series Production Order from the American OEM2023/05/05 -

LiangDao has reached a strategic cooperation with Tencent Cloud to jointly develop an integrated data solution2023/04/19

LiangDao has reached a strategic cooperation with Tencent Cloud to jointly develop an integrated data solution2023/04/19 -

LiangDao won the award of "Outstanding Intelligent Automotive Solution Provider"2023/03/07

LiangDao won the award of "Outstanding Intelligent Automotive Solution Provider"2023/03/07 -

LiangDao was once again awarded the "TOP 100 Innovator" award2023/02/16

LiangDao was once again awarded the "TOP 100 Innovator" award2023/02/16